If you haven't noticed, Jaguar Land Rover is pretty excited about its all-new Special Operations division. It's so amped up, it's doing just about everything in its power to get YOU to realize its existence.

If the Jaguar Project 7 F-Type and Land Rover Range Rover Sport SVR weren't enough to get your attention, then perhaps some vintage-inspired metal will be.

Pebble Beach Preview

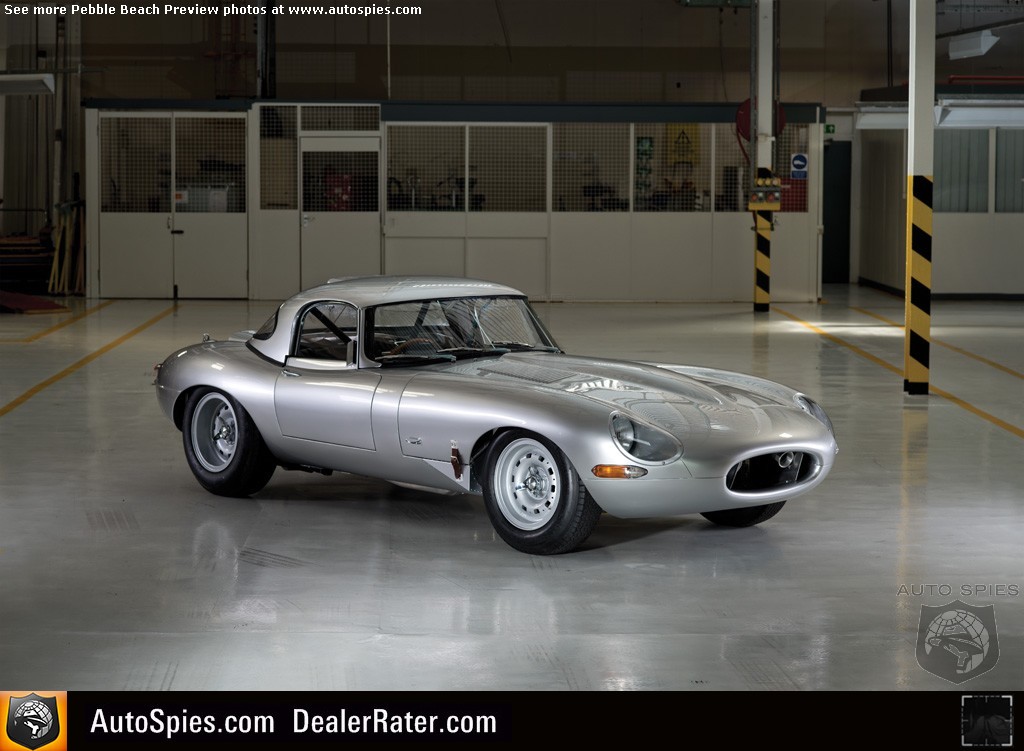

Back in the 1960s, 18 lightweight Jaguar E-Type coupes were to be produced. Only 12 were. Now, Jaguar has announced it will finish the final six vehicles according to factory spec back in 1963. It's a pretty nutty undertaking, if you ask us.

But, if we're honest there's no better place to do this unveil as no one else will appreciate this sort of vehicle like the Pebble Beach crowd.

**For the FULL details, please see below!

Jaguar's press release follows:

JAGUAR LAND ROVER SPECIAL OPERATIONS REVEALS CONTINUATION LIGHTWEIGHT E-TYPE

- Jaguar Land Rover Special Operations has unveiled its continuation Lightweight E-Type – hand-built by skilled Jaguar craftsmen in a new facility at Browns Lane in England

- The new Lightweight E-Type will be produced by Jaguar Heritage, which operates within the Jaguar Land Rover Special Operations division

- Six customer Lightweight E-Type vehicles will be built – each assigned one of the remaining chassis numbers originally allocated in 1963 to the intended 18-car 'Special GT E-Type' project, of which just 12 were built

- The new Jaguar Heritage workshop at Browns Lane is now open to offer Jaguar service and restoration of classic Jaguar models

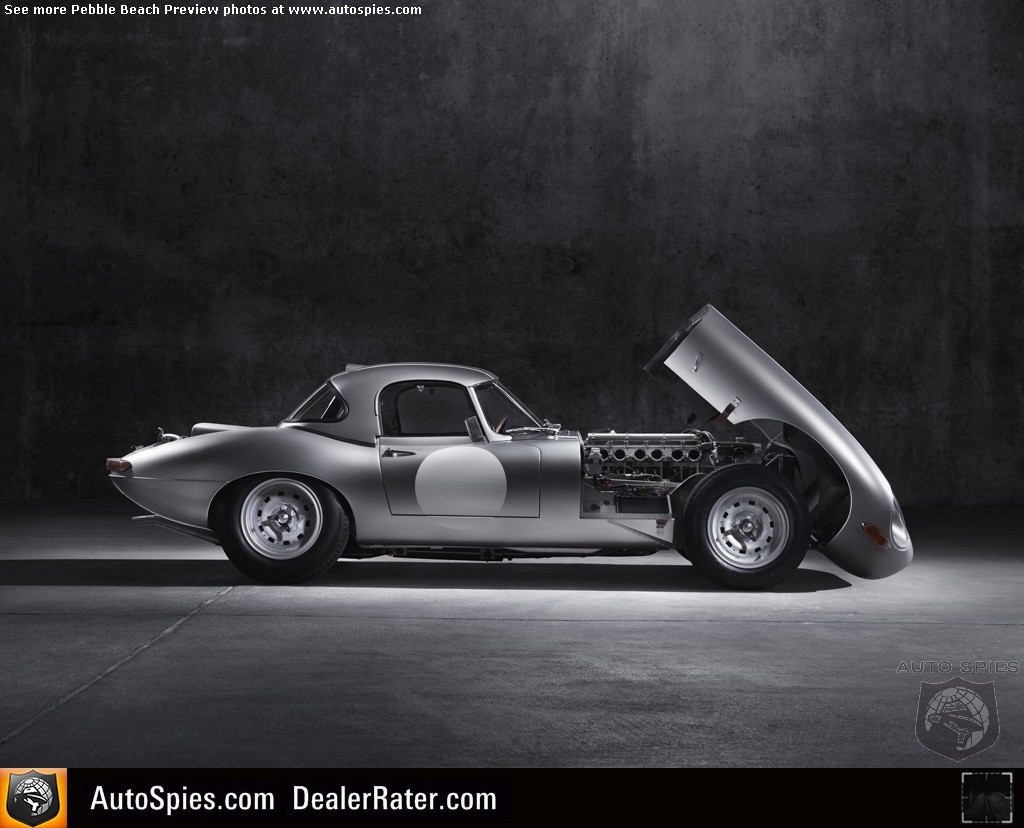

- The specification includes an aluminum body shell, doors, trunk lid, hardtop and hood, and is made to original standards

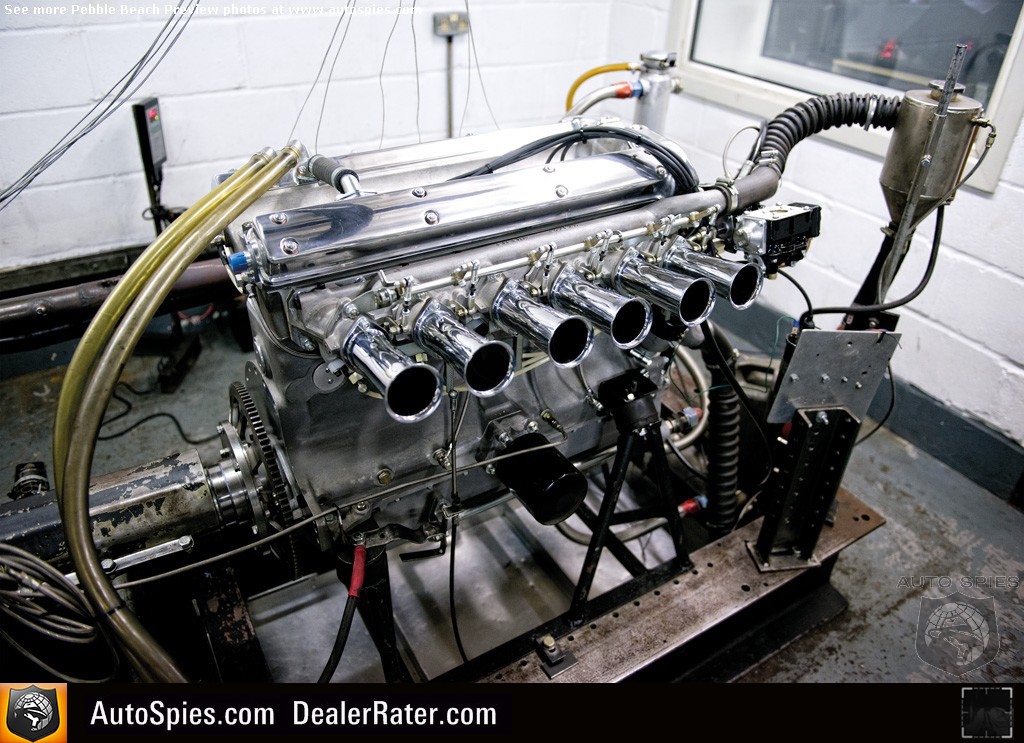

- The classic six-cylinder XK engine features an aluminum block, 'wide angle' aluminum cylinder head and dry sump lubrication

- The cars will be sold as period competition vehicles and all will be suitable for FIA homologation for historic motorsport purposes

- Only 12 of the original Lightweight E-Type vehicles were built, all but one leaving the Jaguar Browns Lane competitions department in 1963 (the last car was delivered in 1964)

- A prototype Lightweight E-Type – ‘Car Zero’ – has been completed and will be revealed on August 14th at the opening reception of the Pebble Beach automotive weekend, the world’s most prestigious classic car event

“Special Operations’ remit is to indulge our most discerning and enthusiastic customers’ passion for our cars – including those from our past. This is why our Jaguar Heritage division exists, and why the new Lightweight E-Type is such an incredibly exciting project.

Pebble Beach Preview

“The E-Type is an iconic car, and the Lightweight E-Type the most desirable of all. To be able to complete the intended production run of 18, some 50 years after the last Lightweight was completed, was an opportunity we couldn’t miss.”

John Edwards, Managing Director, Jaguar Land Rover Special Operations

(MAHWAH, N.J.) – August 11, 2014 – Jaguar has revealed the prototype of its continuation Lightweight E-Type – six of which will be built and sold.

Jaguar announced in May 2014 that it would create six continuation Lightweight E-Type vehicles, each built by Jaguar Heritage, part of Jaguar Land Rover’s new Special Operations division.

Each of the six cars will be built to the specification of the last Lightweight E-Type delivered in 1964 and will be hand-crafted at a new Heritage facility located at the spiritual home of the E-Type, Browns Lane in Coventry, England. The cars will be sold as competition vehicles and all will be suitable for FIA homologation for historic motorsport purposes.

These six cars are the 'missing' six vehicles from the 'Special GT E-Type' project, which originally started in February 1963 with the objective of building 18 cars. Only 12 of the aluminum-bodied Lightweight E-Type vehicles were eventually built and the remaining six designated chassis numbers have lain dormant, until now. The six new cars will carry these unused Lightweight E-Type chassis numbers. A race winner in the hands of a variety of famous drivers during its competitive career, the car achieved worldwide fame, and today, original examples are highly sought after.

In recreating the Lightweight E-Type, Jaguar Heritage has been able to call upon the superlative skills and experience of many talented engineers and technicians currently working at the company. Many employees have historic links with the building of the original E-Type. One employee can trace three generations of service to Jaguar, dating back to the 1960s. The expertise and attention brought to bear on this project ensures the vehicles will be authentic and built to the highest quality standards.

“Operating from a brand new workshop at Browns Lane – now open for the restoration and servicing of customer cars – the building of six new, meticulously crafted Lightweight E-Type period competition cars by Jaguar Heritage is testament to the unique skills within the team. To know those same skills can also be utilized to the benefit of existing classic Jaguar owners means this is a very exciting time for Jaguar Heritage.”

Derek Weale, Director, Jaguar Heritage Business

ENGINEERING

Body

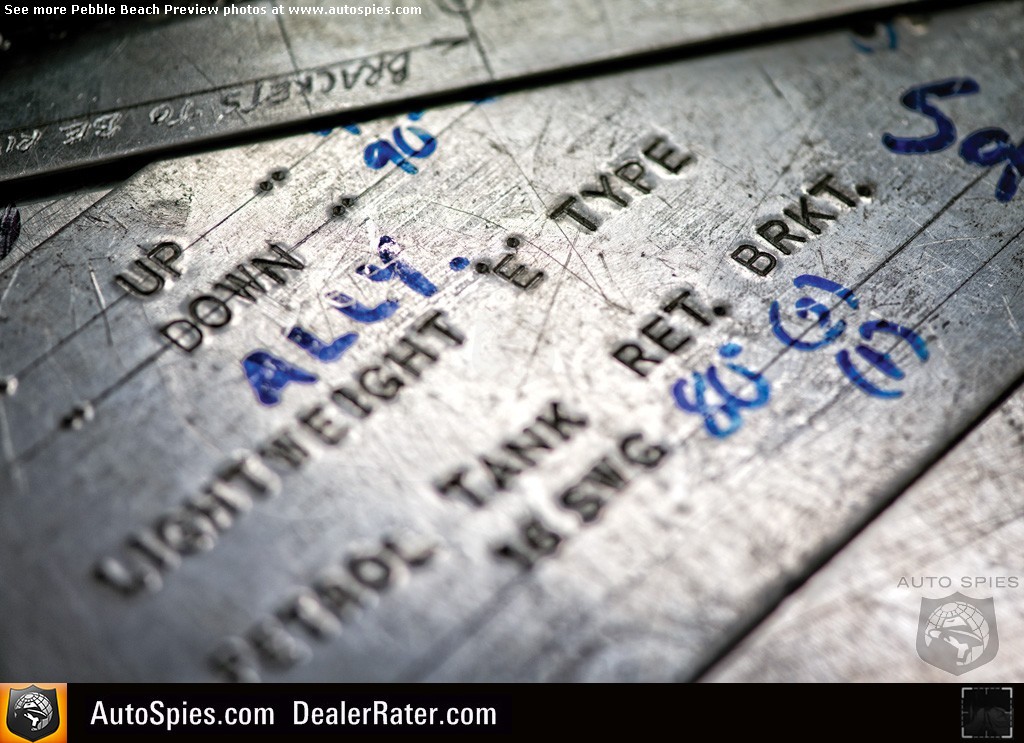

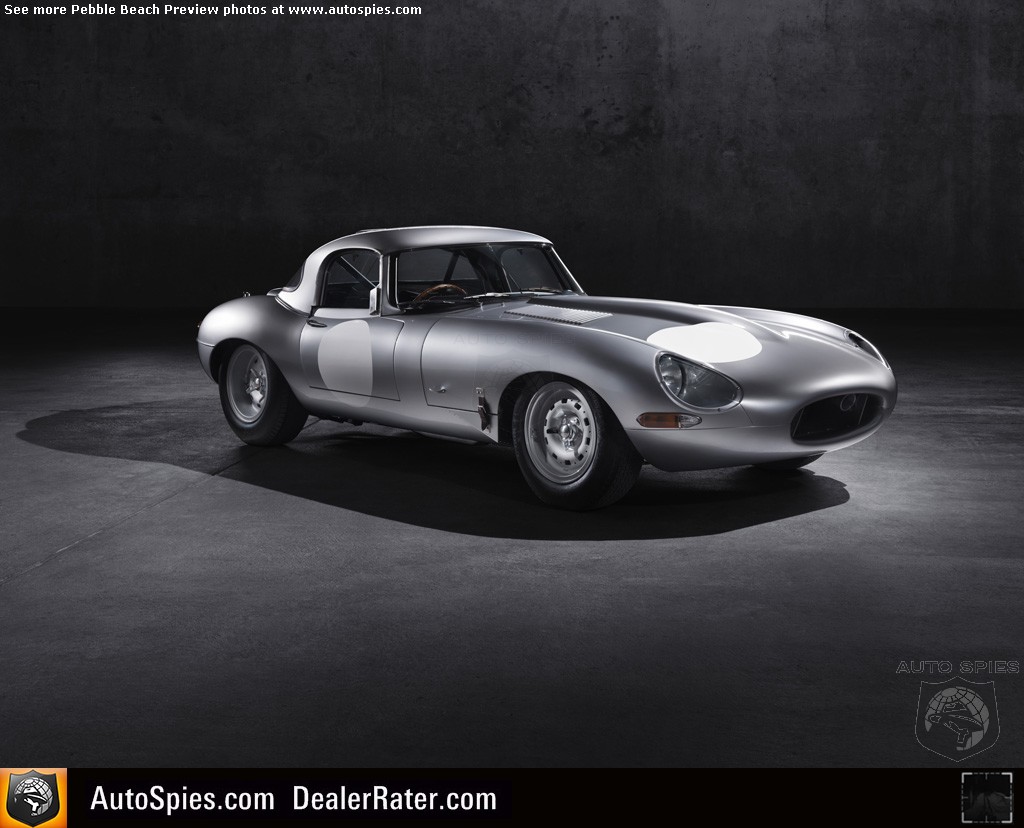

The core component of the Lightweight E-Type is its aluminum body shell, which reduced the weight by 250lbs (114kg) versus the production steel bodywork. When tasked with recreating the aluminum body, today's Jaguar engineers could relate at once to what their predecessors had achieved 50 years before. Even though enormous advances in aluminum technology have been made since the 1960s, the decision was taken not to incorporate modern materials or build methods. While high-strength aluminum alloys and bonded structures would have been invisible, they would not have been true to the original design – nor would they have conformed to the FIA’s homologation requirements for historic racing.

Advanced technology was deployed to ensure the highest quality and most faithful rendition of the Lightweight E-Type. Using advanced scanning technology, the inner and outer surfaces of a Lightweight body shell were digitally mapped. The resulting detailed scan, which recorded dimensions and shape down to a fraction of a millimeter, was assessed to validate how the body was assembled in the 1960s. This also revealed how consistent the structure was side-to-side, and how it could be engineered today to produce the highest quality results.

This digital capturing process gave engineers complete control over the body's 230 individual components. Shapes were optimized before the data was sent to the tool room at the engineering center. Even panels which are unseen within the structure have been faithfully reproduced. To ensure absolute symmetry, one side of the scanned body was used as the baseline, and then mirrored to produce an identical form on the opposite side.

The outer ‘A-surface’ CAD scan was then transferred to the design department, where the surface geometry was finalized. This work ensures that the tooling from which the body parts are produced is as accurate as possible.

Approximately 75 percent of the panels are made in-house at Jaguar Land Rover, with a few very large stampings being supplied by external specialists using Jaguar-designed tooling. The grades of aluminum used for both the under-structure and surface panels are nearly identical to those used for the original vehicles. The body is completed to original Lightweight E-Type Chassis no. 12 specifications, by which time additional strengthening in key areas of the shell had been added.

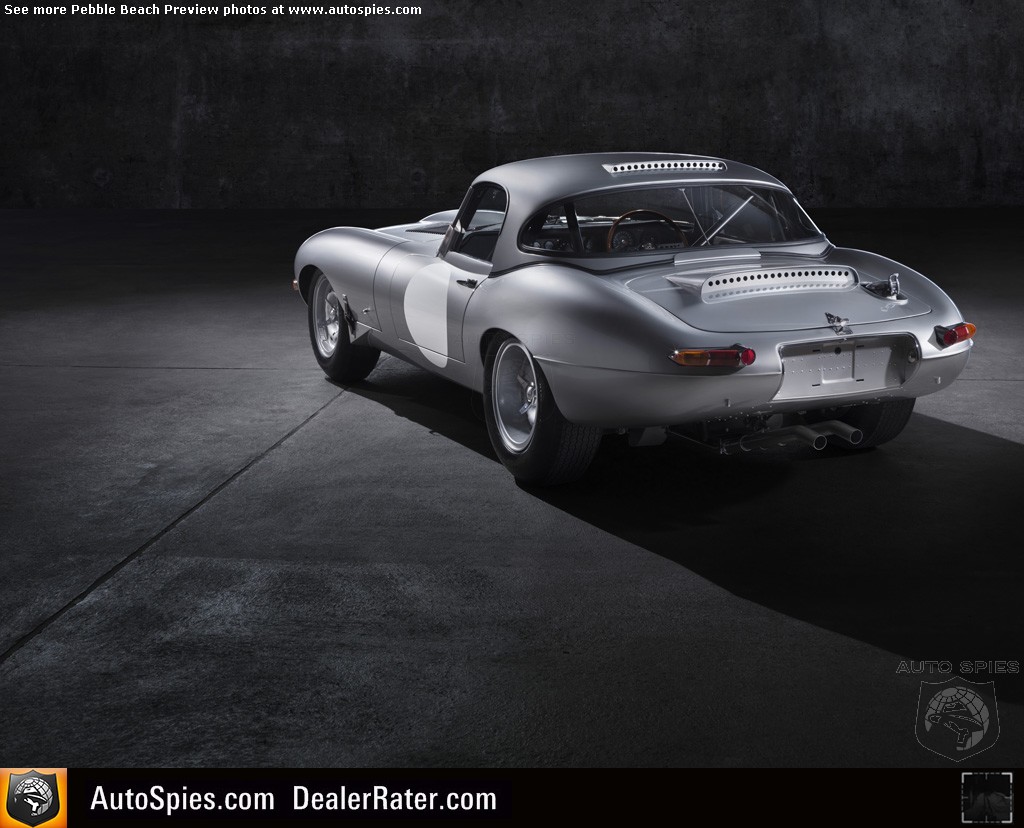

The aluminum body is then completed by the addition of an aluminum hood, doors and trunk lid. As with the original cars, an aluminum hard top is standard.

The development of the body-in-white tooling was undertaken by the same department that builds all Jaguar Land Rover prototype vehicles. The build process and assembly procedures were initially proved out on a prototype known as “Car Zero;” this is an engineering prototype and will not carry one of the six Lightweight chassis numbers.

For the Lightweight E-Type project, Jaguar engineers created a 'grey book' of the type used during the development of new production Jaguar vehicles. This internal document sets out the required quality standards in terms of body shell fit-and-finish and ensures a consistency of build quality for all six new Lightweight E-Type vehicles.

A roll cage is standard equipment and the body includes mounting points for a detachable front extension which is available as an option. The cars are built in a form suitable for FIA homologation for historic motorsport purposes.

Powertrain

The Lightweight E-Type was powered by a highly tuned version of the Jaguar XK inline-six engine. With chain-driven dual overhead camshafts and an aluminum head with hemispherical combustion chambers, it remained an advanced design in 1963 even though it was introduced in 1948 in the Jaguar XK 120.

This was this engine that powered the C-Type and D-Type vehicles to five Le Mans victories in the 1950s. The unit developed for the Lightweight E-Type is based on the 3,868cc (236 cu in) engine which won Le Mans in 1957 in the D-Type. A similar cylinder head is used, but in place of the D-Type's cast iron block, Jaguar introduced an aluminum block with steel liners for the Lightweight E-Type, which substantially reduced the amount of weight over the front wheels.

Another feature transferred from the D-Type is the dry sump lubrication system. This uses a scavenge pump to collect oil from the sump and return it to a separate oil tank. This reduces oil windage, maintains oil pressure during fast cornering and allows for higher oil capacity.

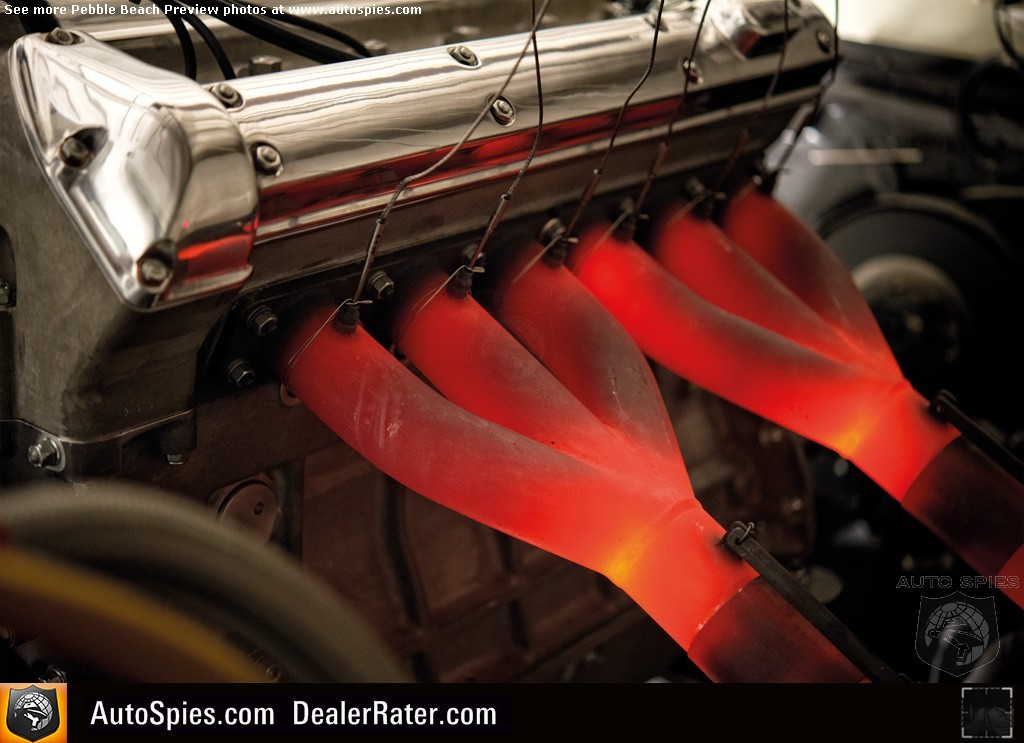

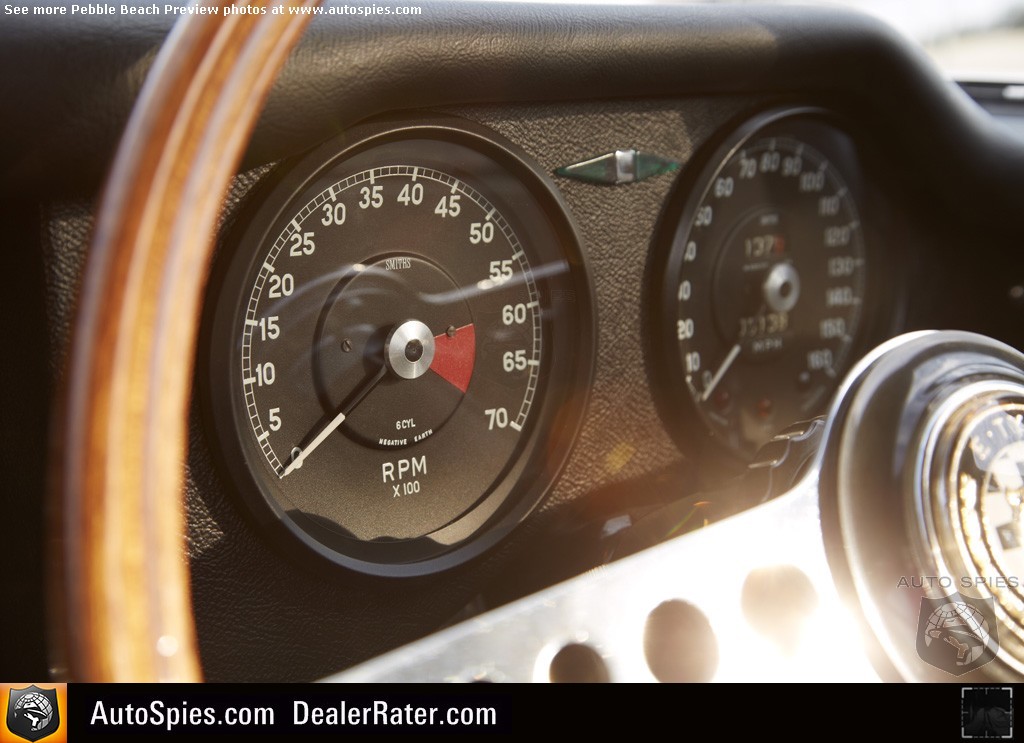

The compression ratio is 10:1 and the car is equipped with three 45 DCOE carburetors. These were homologated for the Lightweight E-Type alongside a mechanical fuel injection system. This fuel injection system is being offered to customers as an option, and is fitted to prototype “Car Zero.” The exhaust manifold is a steel fabrication that leads into dual exhaust pipes and a center muffler at the rear of the car, later terminating in two polished tail pipes.

With over 300 horsepower and torque in the region of 280 lb-ft at 4500 rpm, the car is endowed with rapid acceleration from a comparatively low engine speed – a traditional feature of Jaguar racing engines. A 12 volt negative ground electrical system is used, and the engine benefits from a modern inertia-type starter motor. Other aluminum features include the radiator, oil cooler and expansion tank for the coolant.

The power is transferred to the road via a lightweight, low inertia flywheel, a single-plate clutch, and a close-ratio, four-speed, fully-synchronized manual gearbox. The standard rear axle ratio is 3.31:1 and a variety of final drive ratios will be available. All Lightweight E-Type vehicles will be delivered with the Powr-Lok limited-slip differential.

Chassis

The double wishbone front suspension and independent wide-based wishbone rear suspension (where the drive-shaft serves as the upper link) are set up according to period racing practice, with upgraded shock absorbers controlling the front torsion bars and rear coil springs.

The steering is the standard E-Type rack-and-pinion, with a traditional wood-rim wheel for the driver. Larger (12.25-inch) brake discs are fitted at the front, with the rear brakes being standard E-Type. No servo is fitted.

The 15-inch diameter wheels are the period correct 'perforated' style, and cast in magnesium alloy. Rim width is 7-inches in front, and 8-inches in the rear. Dunlop racing tires are fitted – 6.00 section front, 6.50 section rear, both in CR65 compound.

Final assembly

The unibody is built at the JLR facility in Whitley, England where it is mated to its tubular engine sub-frame – which is stiffened with gussets as it was on the original Lightweight – and then shipped to the JLR Gaydon facility for painting. It is then taken to Jaguar Heritage facility at Browns Lane where the car receives its’ powertrain, suspension, brakes, steering, electrical items, instrument panel and soft trim. This process takes place in a dedicated work area close to where the original Lightweight E-Type vehicles were assembled.

It is at this stage that personal consultation with the customer dictates the final specification for each car – no two of which are expected to be identical.

Prototype “Car Zero” underwent a rigorous shake-down period at our test facility at Gaydon, England. This test included a vigorous shakedown at the hands of Mike Cross, Jaguar Chief Engineer, Vehicle Integrity. Each of the six new Lightweights will go through similar tests to ensure that they meet the required standards in terms of braking, handling and steering.

“In our contemporary Jaguar sports cars our aim is always to achieve an immediacy of response to all driver inputs – and the goal with Lightweight E-Type was the same. For me, its response to steering, brake and throttle inputs – along with the terrific noise it creates – is what makes it such an engaging machine from the driver’s seat.”

Mike Cross, Chief Engineer, Vehicle Integrity, Jaguar

DESIGN

The Jaguar Advanced Design Studio was involved in the project from an early stage, charged with creating the correct trim, together with selecting the materials used and the nature and color of finishes.

“With the Lightweight E-Type, our focus as a design team has been to ensure that justice has been done to the original work of Sir William Lyons and Malcolm Sayer. Meticulous attention to detail has been everything to us in re-creating this car, just as it is in our contemporary Jaguars. I believe the result is a new Lightweight E-Type that is as stunning now as the originals would have been when they were new.” Ian Callum, Director of Design, Jaguar

Connolly leather is used, supplied by Jonathan Connolly, with hides produced to the same specification as those used in the 1960s. This leather is used to trim the competition-type aluminum bucket seat base. The center console is also covered in leather. There will be a choice of seven trim colors.

As befits a thoroughbred GT car where weight saving in all areas is demanded, interior trim is minimal. Customers can opt for a fully-trimmed car and the team can devise bespoke trim packages. This may include door panels, headliner for the hardtop, removable custom saddle-leather floor mats and a cover for the transmission tunnel.

Much of prototype “Car Zero’s” interior – floorpan, rocker and rear areas – have been left unpainted to emphasize the car's aluminum bodywork.

The studio has also selected a palette of six heritage paint colors: Carmine Red, Opalescent Grey Metallic, Silver Metallic, Opalescent Blue Metallic, British Racing Green and Old English White. Various color and trim alternatives are available, as each car will be built to order. The six customers can personally discuss options with Jaguar Director of Design, Ian Callum.

In celebration of the recreated Lightweight E-Type vehicles, Jaguar has also furthered its relationship with the Bremont Watch Company. Bremont will create six bespoke ‘E-Type’ watches, each of which will be offered to customers of the six new Lightweight E-Type vehicles. To read the full Jaguar and Bremont release, please visit: Interactive Jaguar.

Notes to Editors:

· The E-Type was produced between 1961 and 1975 with over 72,500 built.

· The Lightweight E-Type vehicles were built in 1963 (one car was delivered in 1964) as a limited production vehicle by the Jaguar competition department. Twelve complete cars were built in total – 11 are believed to still exist today.

· The Lightweights were homologated for GT competition by being designated a 'standard' roadster E-Type fitted with a number of options. Those options varied from car to car, but the main modifications included all-aluminum unibody and aluminum body panels, aluminum-block, wide-angle cylinder head, a dry-sump 3.8-liter XK engine with optional fuel injection and an aluminum hardtop. All chassis numbers carried an 'S' prefix.

· The Lightweight E-Type vehicles were raced by motorsport legend. Today the remaining Lightweights are front-runners on the historic motorsport scene.

· The newly formed Jaguar Land Rover Special Operations team will focus on delivering halo vehicles, bespoke commissions, heritage products and branded goods.

· The new Lightweight E-Type is the first recreation to come from Jaguar Heritage, which operates within the Jaguar Land Rover Special Operations division.

· Upon completion of its testing and promotional duties, "Car Zero" will be handed over to the Jaguar Daimler Heritage Trust, where it will become part of the permanent collection.

· The new Jaguar Heritage workshop at the historic Browns Lane site in Coventry will offer Jaguar warrantied servicing and restoration of the company’s classic models. Customers can contact the workshop by calling: +44 (0)203 6011544.

LIGHTWEIGHT E-TYPE SPECIFICATION*

Engine System

Engine: Aluminum six-cylinder block, wide-angle cylinder head, dry sump lubrication, lightweight low-inertia flywheel

Displacement: 236.0 cu in (3,868cc)

Bore/Stroke: 3.46in/4.17in (88.0mm/106.0mm)

Valvetrain: 2 valves per cylinder, DOHC

Compression ratio: 10:1

Carburetors: Triple 45 DCOE Weber

Injection (optional): Lucas mechanical, 6.25in (158.7mm) butterfly trumpets

Crankshaft: Steel with steel H-section connecting rods

Power: 340hp/253.5kW @ 6500rpm

Torque: 280lbs ft/380Nm @ 4500rpm

Fuel tank: Mesh-filled 14-gallon (64-liter) capacity

Fuel pump: Standard E-Type

Transmission and Driveline

Transmission: Jaguar 4-speed fully synchronized close-ratio gearbox

Final drive casing: Cast iron, Powr-Lok limited slip differential, axle ratio 3.31:1

Gearbox oil: Castrol

Clutch: Single dry plate

Suspension and Steering

Front: Double wishbone, LWE torsion bars, upgraded anti-roll bar

Rear: Independent rear suspension, lower wishbones with the driveshaft acting as upper links, radius arms, anti-roll bar (Standard E-type rear springs with uprated shock absorber assemblies)

Steering: Standard E-Type rack-and-pinion, adjustable steering column

Brakes

Brake discs (front): 12.00-inch Diameter (305mm)

Brake discs (rear): 11.25-inch Diameter (286mm)

Handbrake: Production E-Type

Wheels and Tires

Magnesium wheels: Front: 15-inches x 7.0J, Rear 15in x 8.0J

Tires: Front - 6.00L15 CR65, Rear – 6.50L15 CR65

Electrical

Battery: 12v - 62 amp / hour

System: 12v negative-ground

Lighting: Tungsten headlamps and standard rear tail-lamps

Ignition: Electronic

Instruments: Smiths Industries

Generator: Production E-Type

Starter: Production E-Type

Control Box: Production E-Type

Wiper motor

and blades: Production E-Type

Exhaust and Cooling

Exhaust: Fabricated steel manifold, steel exhaust system with center silencer box and twin polished tail pipes

Cooling: Aluminum E-Type radiator, aluminum expansion header tank, engine oil cooler, oil sump tank

Overview

Length: 175.3-inches (4,453mm)

Width: 66.9-inches (1,700mm)

Height: 46.5in-inches (1,181mm)

Weight: 2204.6lbs (1,000kg)

Wheelbase: 96.1-inches (2,440mm)

Front Track: 50.0-inches (1,270mm)

Rear Track: 55.0-inches (1,397mm)

BODY TRIM & HARDWARE

Body in white & closures

- Aluminum unibody with stiffened front sub-frame for race engines above 300hp

- Riveted and welded aluminum construction

- Aluminum body closures (hood/doors/trunk-lid)

- Aluminum detachable hard top roof

- 21 louver hood vents

- Black powder-coated roll cage

- Front brake cooling ducts integrated in hood structure

Exterior trim

- Side hood-release handles

- ‘Long range’ aluminum quick release fuel cap

- Body color cabin ventilation air intakes

- Protective car cover (non-waterproof)

- Center hood safety catch

- Oval door mirror upgrade

Interior Trim

- Aluminum bucket seats with increased backrest angle and padded cushions

- Rear-view mirror

- Leather selection from Connolly palette

- Wood-rimmed steering wheel

- Aluminum gear knob and standard hand brake

- Machined metal center panel with toggle switches and push button starter

- Five-point competition seat belt harness

- Black instrument panel with glove box

- Hood and trunk stands

Greenhouse Glass

- Clear laminated front windscreen

- Perspex® (Polymer) side windows and rear screen

- Manual slide side windows

*Figures are manufacturer’s estimates, subject to change according to customer specification.

Pebble Beach Preview