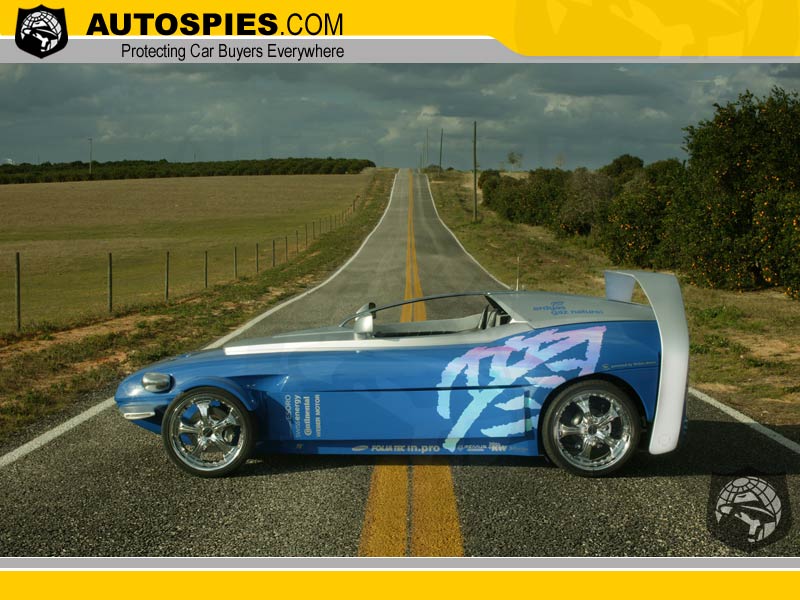

Rinspeed Splash - A Dream Comes True

In what has become a fond tradition Rinspeed Design, the Swiss creative powerhouse for automotive concepts and emotions, presents yet another surprising and astounding attraction at this year’s Geneva Motor Show. To celebrate their 10th concept vehicle the Rinspeed crew has created the

Rinspeed "Splash”.

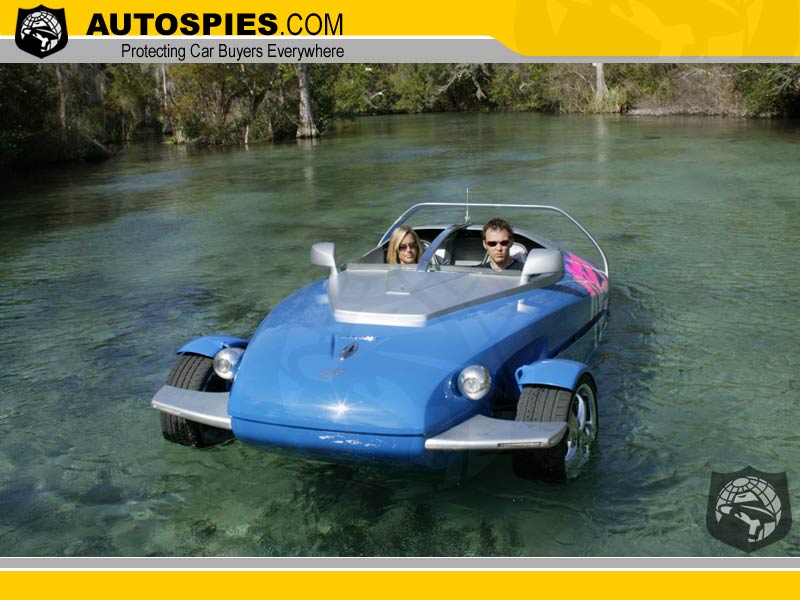

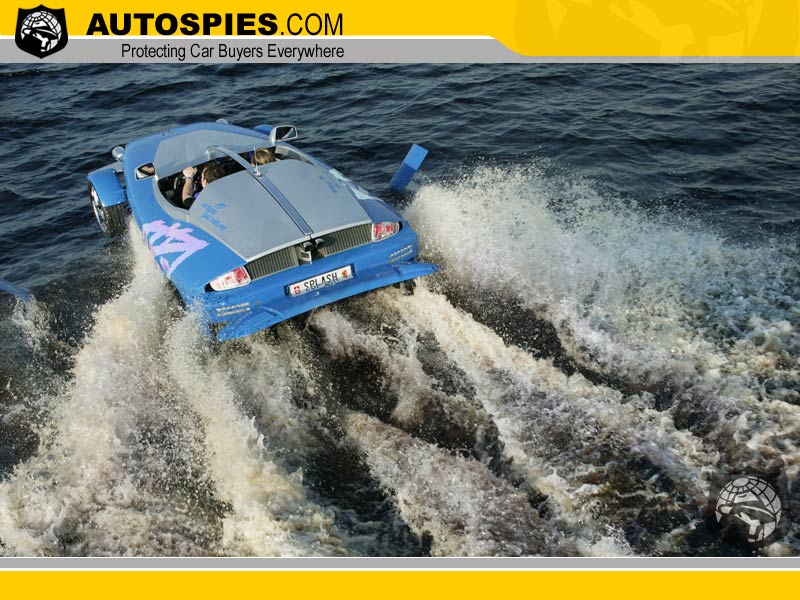

Under the ultra-light carbon-composite skin lies much more than just an agile and lively sports car. The Rinspeed “Splash” is the true incarnation of a really cool and fun sports toy. At the push of a button a cleverly thought-out hydraulic mechanism transforms the sports car into an amphibious vehicle. But that alone wasn’t enough for Frank M. Rinderknecht (48), founder and boss of Rinspeed. A highly complex integrated hydrofoil system enables the “Splash” to ‘fly’ at an altitude of about 60 cm above the water.

On land, on water, and in the air

The almost magical transformation from a street vehicle into a floating and ‘flying’ all-rounder is made possible by an electronically controlled hydraulic system with an array of sophisticated sensors.

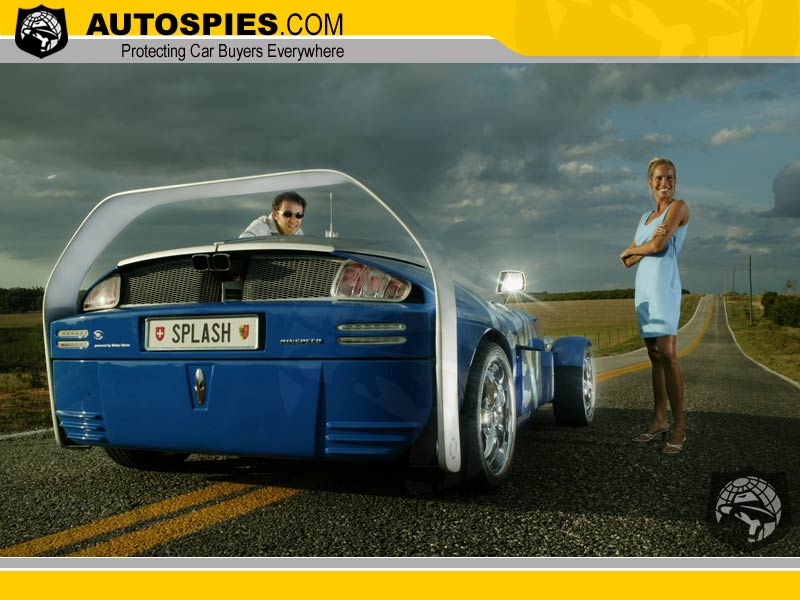

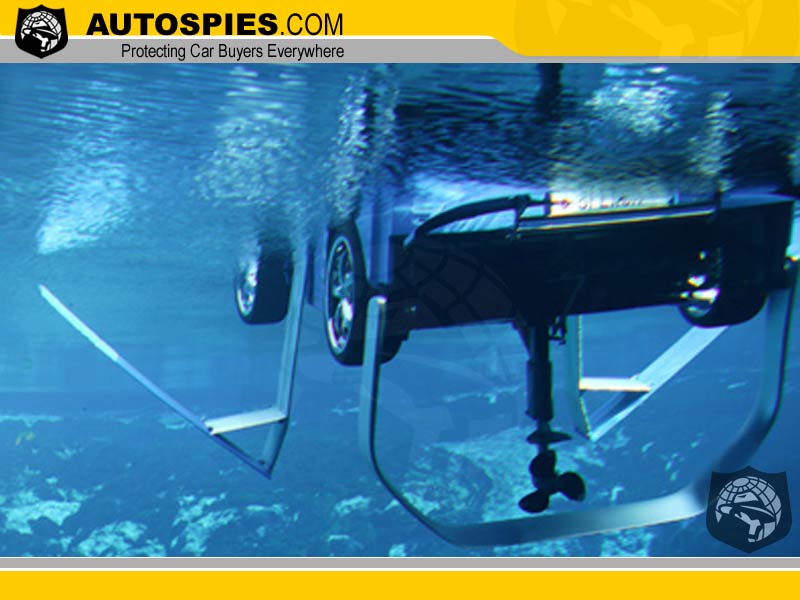

The transformation starts with the nondescript rear panel, which flips up to reveal a Z-drive in horizontal rest position, borrowed from a watercraft. The Z-drive is fitted with a conventional 3-bladed propeller and can be lowered to its fully ‘standing’ position from the cockpit. The position of the drive is infinitely variable, which guarantees immediate propulsion upon entering the water. A custom-designed transfer case sends power to the rear wheels, the propeller or both, depending on the input from the pilot. Starting at a water depth of about 1.1 meters the Z-drive can be lowered all the way to its fully ‘standing’ position. Steering commands are entered via the steering wheel and transferred to the Z-drive.

At a minimum water depth of about 1.3 meters the pilot can deploy a highly complex system of hydrofoils integrated into the sleek body of the “Splash.” The Formula-1 type rear spoiler rotates 180 degrees down and comes to rest below the “Splash.” To the left and right of the high side walls of the cockpit two hydrofoils integrated into the outside skin rotate 90 degrees to point straight down before unfolding into their lifting V shape.

The angle of attack of each hydrofoil can be adjusted individually by the pilot to account for the various operating states. Already at low speeds the vehicle begins to lift itself out of the water. The fully suspended position can be reached at speeds as low as 30 km/h. The unusual vehicle then travels as a true hydrofoil at an altitude of about 60 cm above the water. Even the wheels are free of water contact. On smooth water the “Splash” is capable of reaching a top speed of about 80 km/h (approx. 45 knots).

Naturally the “Splash” can also be operated as a ‘conventional’ amphibious vehicle. With retracted hydrofoils the “Splash” reaches a top speed of almost 50 km/h (approx. 28 knots). That is fast enough for water skiing or knee boarding.

The body of the “Splash” is designed to be watertight. Additional buoyancy chambers provide extra lift. Also borrowed from shipbuilding are a bulkhead design with independent chambers and bilge pumps – in case some water does find its way into the cockpit or the engine bay. Fourteen rubber bellows guarantee freedom of movement of drive train, suspension and steering.

Compact natural-gas power from just 750 cm3

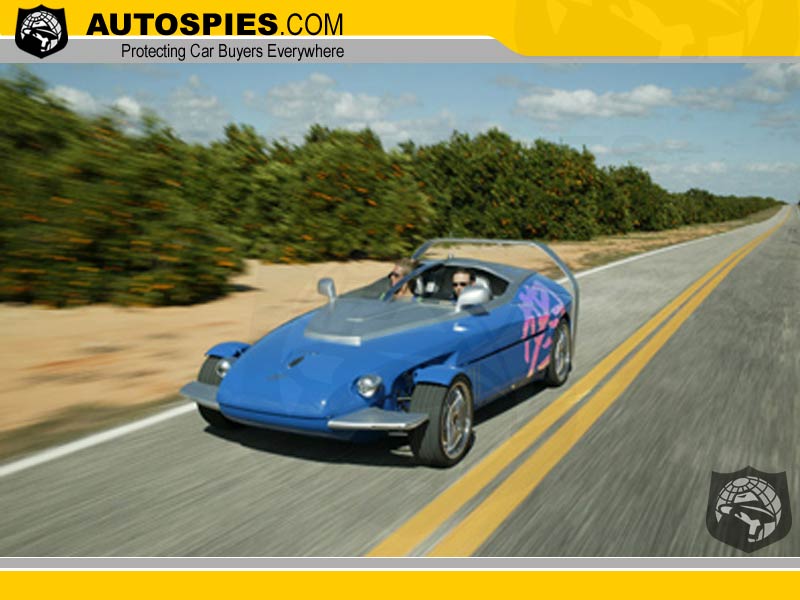

The “Splash” is powered by an environmentally friendly bivalent turbocharged natural-gas engine. Natural gas is an extremely clean-burning fuel that consists almost entirely of methane with near-zero sulfur content. The “Splash” is the world’s first amphibious vehicle to be equipped with this future-oriented engine technology.

Preserving the environment does not mean sacrificing driving fun - and neither does the low overall weight: The turbocharged two-cylinder four-valve engine from Weber Motor powers the watercrafts and snow mobiles from Polaris, albeit as a gasoline-powered engine. In its bivalent turbocharged natural-gas configuration the engine delivers a maximum power output of 140 hp/103 kW at 7'000 rpm. The peak torque of 150 Nm is available at a low 3'500 rpm. Street performance is nothing to be ashamed of: The 825 kg quick-change artist accelerates in about 5.9 seconds to 100 km/h and reaches a top speed of 200 km/h.

No bounds

The sleek lines of the “Splash” draw attention at first glance. However, one of the basic ideas behind the “Splash” concept was to design an automobile whose multi-functional capabilities are not immediately apparent. Hardly anyone will realize that the ‘soft-edge design’ “Splash” can fulfill the age-old child’s dream of almost boundless mobility at the push of a button.

The entire body of the “Splash“ consists of multi-layered carbon composite, a state-of-the-art plastic mainly used in Formula One racing. It offers exceptional stability at a low specific weight. The striking bodylines of the “Splash” are the expression of the fine art of engineering. The low windshield protects against drafts and its tinted Folia Tec glass contributes to the futuristic chrome look.

The sporty stainless-steel exhaust system from Remus provides the adequate powerful engine sound. The chrome-plated dual exhaust tips give the “Splash” a unique and highly dynamic rear appearance.

The lightweight body sits on a suspension custom-developed by KW automotive. It features inboard shock absorbers, adjustable ride firmness and height. The suspension engineers succeeded in creating a suspension that represents a perfect synthesis of ride comfort and sporty handling characteristics.

In.pro. custom-developed chrome-plated bi-xenon headlamps for the “Splash” as well as LED taillights. The latter not only represent the beginning of a new design trend, their ability to come on almost instantly also contributes to the prevention of accidents.

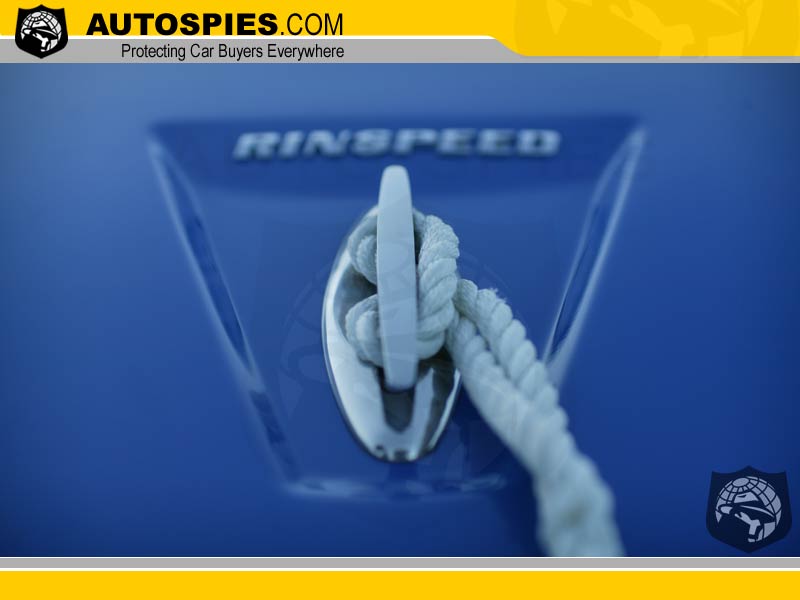

Aye aye, Captain

The interior of the “Splash” clearly pays tribute to its maritime qualities. Lightweight and waterproof plastics cover the tubular frame and the ergonomically shaped plastic seats. The small sport steering wheel is perfect for the agile handling characteristics of the lively and highly maneuverable “Splash.” A number of chrome-plated shift knobs, which govern the amphibious functions and the angle of attack of the hydrofoils, exude an atmosphere reminiscent of an airplane cockpit.

Hydroplaning - on water only

The Rinspeed “Splash“ runs on Continental SportContact tires with 17-inch diameter in front (215/35-17) and 18 inches in the back (225/35-18). The Continental tires combine environmentally friendly design, very good handling characteristics and excellent grip. They are mounted on chrome-plated aluminum rims (7x17“ front, 7.5x18“ rear) custom-made by Barracuda.

Swiss made

Esoro

Frank M. Rinderknecht used highly advanced technology and a Swiss-based network of top automotive specialists for his project. Although there is no automobile production in Switzerland to speak of, there is a very active automotive supply industry there. Many highly innovative prototypes have been developed and manufactured in Switzerland^.

engineered by Esoro - What you dream is what you get

For the fifth time the Swiss engineering company Esoro was hired to serve as general contractor for the entire vehicle project. Esoro was responsible for project management, engineering, design and manufacturing of the Rinspeed Splash.

Esoro masterfully met the challenge with the help of its highly competent suppliers Naval (marine), Swissauto (drive train adaptation) and Protoscar (styling). Starting with initial concepts, it took the highly skilled development team just seven months to realize the entire project including tests on the road, on the water and in the “third dimension” by flying at high speed over a lake.

Esoro has been a contract developer in the areas of automotive production, lightweight design and plastics technology for 13 years. During this time it has gained a well-deserved reputation for excellent efficiency and innovative solutions not just in these but also in other fields, including fuel-cell vehicles and prototype design. Esoro has impressively demonstrated its expertise with numerous extraordinary prototypes.

And even more: Esoro developed the new E-LFT production technology, which makes large scale production of high-strength and lightweight composite parts affordable. E-LFT composite parts weigh 30-50 percent less than comparable steel parts. Furthermore another production process for similar parts, but small scale niche markets is near completion.

gasmobil - A Strong Partner

The spread of natural gas as a fuel of choice is supported by the shareholders of gasmobil AG and local natural gas suppliers. Natural gas is a meaningful and environmentally friendly alternative fuel, which can make a significant contribution to the reduction of harmful pollutants, especially in congested urban areas. When combined with CO2-neutral biogas, the pollution emission levels are improved significantly. The most important arguments for natural gas and biogas as fuels: Lower pollution levels compared to gasoline or diesel; better mileage in hybrid versions and therefore also more economical, lighter and cleaner refueling; subsidies for the purchase of any new vehicle in some cantons; manufacturers’ guarantees; and vehicle safety similar to all other passenger cars.

Natural gas and biogas as the fuel of choice - the future is now

gasmobil, SwissEnergy and Rinspeed - three strong partners, who develop vehicles for everyday operation and future visions for mobility. The vehicles jointly displayed are fueled by environmentally friendly natural gas or biogas: the VW New Beetle Cabriolet uses standard drive train technology. The VW Golf Variant has a novel exhaust treatment concept, which was developed for gasmobil AG together with ETH Zurich, the Swiss Federal Department of Energy (BFE and SwissEnergy), the Paul Scherrer Institut Villigen (PSI), Automobil- und Motoren AG (AMAG), the den Industriellen Werken Basel (IWB), as well as the Gasverbund Mittelland AG as part of a Novatlantis Project entitled “An Innovative Vehicle Fleet For Basel”. The splash demonstrates that even unusual drive train concepts can be used both on the road and in the water every day.

Fuel supply - no problem in Europe

Employing natural gas and biogas means taking another step on the way to less crude oil dependence for the world's economy. The tremendous environmental potential of natural gas cannot only be exploited in static use, but also by road vehicles to reduce harmful pollution levels from soot, nitrogen oxide, CO2, and hydrocarbons. Furthermore, natural gas motors reduce noise pollution levels compared to conventional units. These drive technologies are mature and market-tested. It is hard to find a manufacturer which does not have one or more models in its program. In addition to this, the gas station network in Switzerland and the rest of Europe is being developed rapidly. Round-the-clock supply is guaranteed.

SwissEnergy’s Ongoing Commitment

Through its SwissEnergy program, the Federal Office for Energy has been promoting the use of natural gas and biogas for over 10 years. Initially it mainly supported research work. Between 1996 and 2000 SwissEnergy supported a pilot and demonstration project with “Kompogas” vehicles in the region around Zurich. Over 100 vehicles were put on the road as part of the project and the responses by users were very positive.

Meanwhile, the Swiss gas industry has been establishing a network of natural gas refueling stations and the car industry has been expanding its range of natural gas and biogas vehicles. For three years now, Gasverbund Mittelland AG, Rinspeed AG and SwissEnergy have been working closely to promote natural gas and biogas as a motor fuel. The concept cars designed by Rinspeed AG enable the public to visualize the possibilities offered by natural gas as a motor fuel and serve^to dispel the prejudices against this young and clean form of fuel that unfortunately continue to prevail. The use of natural gas and biogas as motor fuels helps to spare valuable resources and generates lower emissions than traditional motor fuels. Natural gas produces around 20% lower emissions per energy equivalent of the greenhouse gas CO2, and renewable biogas fuel is even CO2-neutral.

A word from our technical partners

Barracuda / Aerotechnik

Barracuda Racing Wheels - Outstanding Designs

Barracuda’s alloy wheel program presents itself in new and unmistakable designs with fresh and trendy colors. Many individual finishes as chrome, dark, light and shiny silver and outer ring bolt colors are offered.

The basic idea behind every Barracuda product is the uncompromising sportiness, expressed in the very modern stylistic idiom.

The ingenious Japanese American designer Ichiyanagi Satoshi is responsible for many of the creations. He sets lasting trends in the world of alloy wheels in the recent past.

The Voltec T3 wheel shows the uncompromising sportiness of the classic Cup wheel paired with the cool elegance of sparkling chrome. The open building method makes the wheel light weight and shows of the technology of the brakes.

Continental

Rinspeed Splash: On the Road and in the Water with Continental Tires.

The Rinspeed Splash makes it possible to travel on the road, in the water and in the air: The ultra-light concept vehicle can reach speeds up to 200 km/h as a sports car, 50 km/h when operating normally in the water and 80 km/h when functioning as a hydrofoil. When selecting a tire for the two-seated sports car, Rinspeed decided on the ContiSportContact 2 to ensure maximum grip for starting up, braking and cornering.

To guarantee that the 750 cc small but 107 kW (140 HP) powerful aggregate has just the right grip on asphalt, Rinspeed equips its Splash with ContiSportContact 2 tires of the size 215/35 R 17 on the front and 225/35 R 18 on the rear axle. The two-seater is thus ideally equipped for acceleration, braking and cornering to ensure a safe and sporty trip on the way the water.

Traditionally, Rinspeed reveals a new concept vehicle at the Geneva Motor Show, unifying new dimensions of sportiness, flexibility and environmental compatibility. With the Splash, the "Swiss dream factory" has tackled the dream of mobility on land, in the water and in the air. The result is the Splash: Powered by an extremely effective but just 750 cc natural gas engine with 107 kW (140 HP), the vehicle, weighing in at a mere 850 kg, can reach speeds of up to 200 km/h on the road. When traveling on water with its pop-up propeller, it can go up to 50 km/h (27 knots). And when its wings - which usually function as spoiler - are lowered, the Splash cruises across lakes and rivers even faster: The propeller shaft stays in the water, the Splash lifts up above the surface and accelerates to 80 km/h (43 knots). And the dream of one vehicle providing sporty and environmentally friendly travel on land, water and air becomes a reality.

The Continental Corporation is a leading supplier of tires, braking systems, chassis components and technical elastomers. In 2002 the company realized sales of EUR11.4 billion with a worldwide workforce of around 64,500.

The tire division is an official partner of the FIFA WM Germany 2006TM. Further information in this regard is available under www.conti-online.com and under www.contifanworld.com.

Foila Tec® - A Companion In All Elements

The Nuremberg-based Carstyling Factory Folia Tec® has always supported unconventional, radical and forward-looking ideas. The best example for this practice is the long-standing partnership with the Swiss design and engineering company Rinspeed. This year too - in time for the 2004 Geneva Auto Show - dreams come true: the sensational Splash drives, swims and takes off with a total of ten uplifting Folia Tec® products on board. Short Shift Gear Lever plus Brake Shift Handbrake Lever ensure optimal Stop and Go performance. The Kill Switch On/Off provides the emergency functions. Lumax Sky Neon-Kits show the Splash in the most favorable light, while the Strobe Lamps - water- and shockproof - are insensitive even to water. For controlling the element air in the tyres the car engineers are using Air Caps Valve Caps. Folia Tec® Shoulder Pads prevent seatbelts from pinching by distributing their pressure more evenly over the body, so allowing the pilots to experience all three elements with maximum convenience.

Folia Tec® - Company Profile

Folia Tec®‘s styling activities comprise three fields: Car-, Bike- and Boatstyling. Founded 22 years ago by managing partner Michael Böhm, the Nuremberg-based Folia Tec® Böhm GmbH + Co Vertriebs KG initially focused on marketing Autoglass Films from America. Adopting a systematic brand development strategy – in the meantime Folia Tec® is an international registered trademark – the company then began to supply the specialized car accessories trade. Today in Germany 11 major and 8 regional centers are supplying the specialized car accessories trade and the StylingTeam-Partners. The complete range of Folia Tec® products is also available from the Folia Tec® Performance Centers in Backnang, Bergen/Rügen, Großröhrsdorf/Dresden, Kulmbach, Cologne, Heilbronn, Waiblingen, Munich and Nuremberg, as well as in Goldach/Switzerland, Golbey and Ozoir/France, Moscow/Russia, Vienna/Austria, Areceife/Lanzerote, Seoul/Korea and Shanghai/China.

With a staff of 50 the company is designing and producing a wide variety of do-it-yourself products, including AutoglassFilms, interior and exterior carstyling accessories, Cardecor, wheel and engine accessories, LED/Neon lighting products and Special Effects.

Folia Tec‘s® second „pillar of success“ are the StylingTeams. The franchisees are provided with the required know-how for the professional film fitment. Today over 200 StylingTeam-Stations exist in Germany and 12 other European countries. In-depth training is provided in Folia Tec‘s® StylingTeam College.

Today Folia Tec® is one of the leading suppliers of products for individual Car-, Bike- and Boatstyling. This leading position has been achieved by the consistent development of the Folia Tec® brand for more than 20 years, making Folia Tec® a household name in the specialized trade today. In foreign markets the Car-, Bike- and Boatstyling ideas from Nuremberg are also very popular both among the trade and among the young clientele, with high-circulation consumer catalogues produced in several languages reaching a wide audience. An all-year advertising campaign in national and international specialist journals plus a comprehensive media information service are designed to support the activities of the trade and of the StylingTeam-Partners. On the web Folia Tec® can be found on www.foliatec.de or www.foliatec.com. In the virtual community its online catalogue has already earned Folia Tec® the reputation for being a trendsetter. Folia Tec‘s® pre-formed Autoglass Films are featured on www.pro-shape.de, while www.cardecor.de presents the ultimate ideas for unconventional Race-, Tattoo- and Tribal-Decors.

in.pro. - Everything That Makes Car Driving Fun

Following up the many years of successful involvement in the Rinspeed Concept cars over the last few years (Advantige Rone, Rinspeed Presto, Bedouin), the globally operating car accessories specialist based in Northern Germany is once again taking an active part in various new developments. in.pro. represents 25 years of high quality and innovative car accessories in the areas of design, interior, comfort and fun. The more than 4,000 in.pro. products excite just as much the hobby engineers and do-it-yourself fans as the drivers of normal “standard” production models. Virtually everybody can benefit from great value for money and improve the appearance of their car (e.g. by fitting design products such as clear glass headlamps), or the comfort (for instance, with retrofitable remote controls), or the safety (e.g. by installing alarm systems or parking aids). Our own dedicated development team and a network of scouts aware of what the target group trends are the source of our new ideas. Implementation – from the initial idea to dispatch to the customer – is the responsibility of over 45 staff pro- centre in Henstedt-Ulzburg and 300 dealerships worldwide.

Decisive for the participation in the Splash Project was the ability to implement the employed products in series: “The splash is the perfect realization of visions – in engineering, function and design”, revealed in.pro. boss Jörg Knoblich, “and for us the possibility of creating and testing technically complex customized solutions that later find their way into production series. Many Splash in.pro. products can be viewed in the current catalogue or will soon be made available to in.pro. customers.”

LED tail lights and indicators

LED lights not only last longer and provide the same uniform light output, but also enable drivers to customize the illuminant. The designer LED tail lights in the Bedouin were already reason for excitement last year. These were slightly modified in.pro tail lights for the Opel Corsa that became available in the shops just a few weeks after the launch of the Bedouin. The Splash will also see LED indicators developed for the Alfa 147. Other LED light units such as, for instance, tail lights and side indicators will form the basis of the high quality and innovative series accessories available in the future.

Bi-Xenon lights

The Splash headlights are not only a very special head turner, but also a technical delight. The in.pro. development team milled the headlight units from a solid block of aluminum and integrated the finest Bi-Xenon technology. The result is a cool headlight look precisely matched to the Splash contours and the best possible light efficiency for illuminant minimum size.

KW automotive

KW automotive GmbH is one of the leading world wide suppliers of height adjustable suspension kits since many years. The KW engineers were especially challenged with the 2004 Rinspeed project car to reach the highly set goals and to support the leadership in technology in the suspension segment of KW automotive. A KW coil over suspension in stainless steel had been developed for the Splash featuring separately adjustable twin tube hydraulic shocks for both pressure and rebound.

A part of the optimal performance, the best possible protection against corrosion was asked for the use in the Rinspeed Splash. As KW automotive is the only supplier offering coil over suspensions in stainless steel, the choice for the company in Fichtenberg/Germany was therefore further facilitated.

Remus

Stainless steel, laser precision, optimal performance and the typical Remus sound, these are the four characteristics that distinguish Remus sport exhausts. Through their involvement in motorsports and their close cooperation with world champions like Jacques Villeneuve or Damon Hill, European champions and other champs, Remus gains important knowledge for the development and production of high quality silencers. High quality comes first for Remus and it is attained by using stainless steel in combination with other high grade raw materials. This combination used by Remus technician’s guarantees best results under thermal and mechanical stress. Therefore Remus takes a leading position in the favor of the public. The success of the sponsoring activities of Remus is impressively documented by the reader’s survey of numerous specialist publications since many years.

Weber Motor

Introduction the Weber Motor AG

As an independent manufacturer of internal combustion engines, the Weber Motor AG was established on December 17, 2001 as an additional member of the Albert Weber Group, a successful automotive supplier located in the city of Markdorf near the Lake of Constance. For over 30 years the Albert Weber Group has focused on its quality leadership, specializing in the high-tech machining of engine and gearbox components. With the Weber Motor AG, the Group has taken the step to becoming a system supplier. The objective is to position the Weber Motor AG as a specialist for highly efficient internal combustion engines for automotive, industrial and recreational applications.

The MPE 750 Multi-Purpose Engine originated already in 1996, when the Albert Weber GmbH was on the look-out for an engine fitting an exceptional vehicle concept. Back then, none of the available engine concepts on the market could fulfill such requirements as reducing the engine weight as well as the available engine compartment by half for a Golf-class vehicle, and still making it into the category of the 3-liter automobile.

With the insight having to come up with something new, the Albert Weber GmbH began to search for a competent development partner, who was finally found with the Swissauto Wenko AG, an engine development team situated in Switzerland. The Swissauto Wenko AG appeared to be predestined for this job, as they had visualized the future potential of the “light and compact” concept and at this point could already resort to initial experience in the development of such drive units.

The Swissauto Wenko AG proved their competence not only through the development and technical support of racing engines for the eight-time sidecar motorcycle world champion, but also through the successful development of an opposed cylinder engine concept with which Greenpeace was able to prove the realization of the 3-liter car to the automotive world in 1995. Another highlight, of course, was the engine development for the Swatch-Mobil that in conclusion led to the exceptional idea of Daimler Chryslers’ “Smart”.

In 1998, the development partners were proud to present the first running prototype of the MPE 750 on the test bench. Afterwards, the convincing characteristics of the MPE 750 laid the foundation stone for the signature of the supply contract between Matra Automobile and the Albert Weber GmbH in early 2001. It was also this contract that led to the formation and structure of a new organization for the development, production and delivery of the Weber Motor® MPE 750 engine.

An additional challenge to the series development of the Weber Motor® MPE 750 engine was posed for the young enterprise with the development of a complete engine operating system, which was completed with the kick-off of the series.

In order to realize production at the Markdorf location, the Weber Motor AG focused on a high degree of automation in conjunction with the use of flexible production systems. For the first time, complete tracking of the components throughout the complete production cycle of an engine was realized in an industrial dimension. Making these starting points happen also formed the main focus of the activities in 2002/2003. Within the framework of its growth, the Weber Motor AG has created more than 100 highly-qualified jobs at the Markdorf location.

In December 2003, the successful start of series production for the two Weber Motor® MPE 750 engine varieties with 110 and 135 hp were celebrated. The objective is to continuously increase the annual volume from 12.000 units in the beginning to 50.000 units, and thus establish ourselves as a manufacturer of solutions for high-end niche products.

Downsizing Pure - The MPE 750 Multi-Purpose-Engine

The Weber Motor AG, which was formed in late 2001, has developed a completely new, extremely compact and powerful 2-cylinder 4-stroke engine with a displacement of 750 ccm named the MPE 750 Multi-Purpose Engine. As the first representative of an engine family from 1 to 4 cylinders, this engine stands for an engine concept that is modular and allows for completely versatile applications.

The design versatility of this engine concept includes not only aspirating engine varieties, but also turbocharged or compressor-charged varieties with a mean pressure exceeding 22 bar. These values describe a new generation of series production engines, especially when contemplating 2-cylinder engines.

Upon development of the MPE 750, the prime target was to meet the extreme requirements of a downsizing concept. Among other things, this led to a new design of the crank drive concerning dimensions and material selection. This development was supplemented by pursuing the parallel-twin configuration, utilization of an aluminum housing with tension rods as well as designing the cooling circuit with the least possible volume.

Additional characteristics, such as the possibility of power take-off on either engine side, the cylinder head that can be assembled reversed, the possible rpm range up to 9000 rpm and the wide power range from 15 kW to 100 kW of rated power allows for the MPE 750 to be used for the most varying applications.

With the focus on integrating as many components of the Weber Motor® MPE 750 engine as possible, the effort of extending the engine family by a 4-cylinder unit, with the goal to cover additional niches in the recreation and particularly in the automotive market, is currently in progress.